Introduction: The Core of Reusable Safety

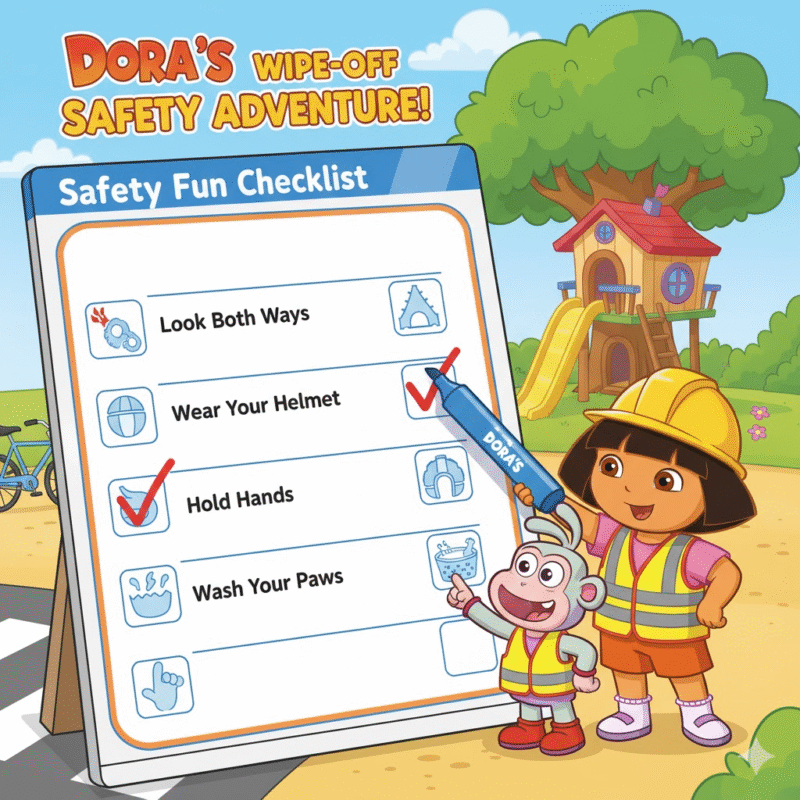

In the world of safety training, the term “Dora Safety Wipe Off” holds a dual meaning. For parents and educators, it conjures up the Dora the Explorer Safety Wipe-Off Workbook (published by Learning Horizons around 2004) that taught children fundamental safety rules through fun, reusable activities. For professionals, however, it represents a critical concept: the power of reusable, wipe-off safety tools (like laminated checklists or digital forms) to ensure daily compliance, boost training effectiveness, and reduce waste.

Whether you’re teaching a preschooler about fire safety or training a worker on machine lockout procedures, the core principle is the same: consistent repetition and verifiable documentation are non-negotiable for safety. This article explores how modern “wipe-off” solutions drive a robust safety culture and maintain strict regulatory compliance across any industry. We will show you how to apply this simple concept to achieve excellence in your Environment, Health, and Safety (EHS) program.

Why Reusable Materials Outperform Traditional Paper Checklists

The traditional method of printing stacks of paper checklists for daily inspections, machine start-ups, and pre-shift hazard assessments is often expensive, prone to errors, and difficult to audit. Reusable safety materials—the professional equivalent of a “wipe-off workbook”—solve this compliance and cost problem by providing a durable, interactive, and sustainable alternative.

The E-E-A-T Advantages of the “Wipe-Off” Method

Implementing reusable safety materials is a hallmark of an expert, authoritative EHS program. They demonstrate accountability and professionalism.

- Cost Efficiency and Sustainability (Expertise): Reusability drastically reduces paper waste and printing costs, showing leadership in sustainable operations.

- Enhanced Worker Engagement (Experience): The tactile nature of writing or checking boxes encourages workers to actively participate, improving retention and attention to detail compared to passively reading a document.

- Durability and Real-World Use (Trustworthiness): Laminated or synthetic materials resist common industrial contaminants like grease, dirt, and water, ensuring that compliance records remain legible and intact, even in harsh environments.

- Immediate Corrective Action (Authoritativeness): In a training scenario or inspection, mistakes or missed steps can be erased and corrected instantly, ensuring the procedure is learned correctly before the task begins.

Expert Quote: “Safety training is not a one-time event; it’s a daily ritual. Reusable checklists are the physical tools that embed this ritual into the core of your operational flow.”

Modern Applications of the Wipe-Off Safety Principle

Adopting a “wipe-off” methodology today extends far beyond a simple dry-erase board. The concept has evolved to include sophisticated digital solutions that offer the same benefits of reusability and instant updates, paired with powerful data tracking.

Physical Laminated Checklists and Visual Aids

For shop floors, heavy equipment, or sites with poor connectivity, physical reusable tools are essential.

- Machine Inspection Cards: Small, custom-designed, laminated cards carried by technicians to perform pre-shift inspections (e.g., fluid levels, horn function, guards in place) on forklifts or machinery before operation.

- Lockout/Tagout (LOTO) Procedure Boards: Boards placed directly at energy sources detailing the LOTO steps. Workers sign off with a dry-erase marker, visually confirming the isolation of the equipment.

- Emergency Contact Stations: Large, centrally-located dry-erase boards used to post and frequently update emergency contact numbers, evacuation routes, and the designated safety officer for the day.

Digital “Wipe-Off” Tools and EHS Compliance

The most advanced solution today is the digital checklist, accessible via tablets or mobile apps. These platforms allow users to virtually “wipe and restart” a form daily while achieving maximum regulatory compliance.

- Auditable Record-Keeping: Digital inspections are instantly timestamped and geotagged, creating an irrefutable, auditable trail that satisfies OSHA and other regulatory bodies.

- Automated Accountability: If a critical check fails (e.g., “PPE missing”), the system can automatically flag the issue, assign a corrective action to a manager, and track its resolution.

- Data-Driven Safety: Over time, the data collected from these frequently “wiped off” and completed forms can be analyzed to identify high-risk trends or areas that require additional training.

By moving to digital, a company can ensure that even when an inspection is completed and the virtual “ink” is cleared, the data and proof of compliance are permanently and securely stored.

Achieving EHS Compliance: The Auditable Trail

Regulatory standards require not just that safety procedures are in place, but that they are followed and documented. Reusable systems, when implemented correctly, streamline this often complex process.

Key Regulatory Requirements Met by Reusable Systems

| OSHA Compliance Area | How Wipe-Off Materials Help |

| Hazard Communication (HazCom) | Laminated SDS summary sheets allow workers to quickly reference and wipe-down critical information without destroying the document. |

| Personal Protective Equipment (PPE) | Physical or digital checklists confirm workers are checking, inspecting, and donning appropriate PPE before starting a task. |

| Recordkeeping & Training | Digital platforms automatically capture and organize training sign-offs, inspection logs, and maintenance reports, making them instantly accessible for audits. |

Actionable Takeaway: When using physical wipe-off materials for sensitive documentation (like LOTO), ensure a manager photographs or scans the signed and completed checklist at the end of the shift before it is erased, unless you have fully transitioned to an automatically archived digital system.

Conclusion: Securing a Safer Future

The simple educational philosophy found in the Dora Safety Wipe Off Workbook—the idea that learning is most effective when it is repeatable and engaging—holds profound lessons for industrial safety. By committing to reusable training and compliance materials, whether laminated or digital, your organization achieves three core goals:

- Cost Reduction: Minimizing printing and administrative overhead.

- Compliance Assurance: Building a comprehensive, auditable trail of safety due diligence.

- Cultural Excellence: Embedding routine, interactive safety practices into the daily workflow of every employee.

Invest in the modern “wipe-off” approach today to secure a safer, more sustainable, and ultimately more compliant future for your entire workforce.

| You May Also Like: Optimus Prime The Brave Robot Leader Loved by All Kids |