Introduction

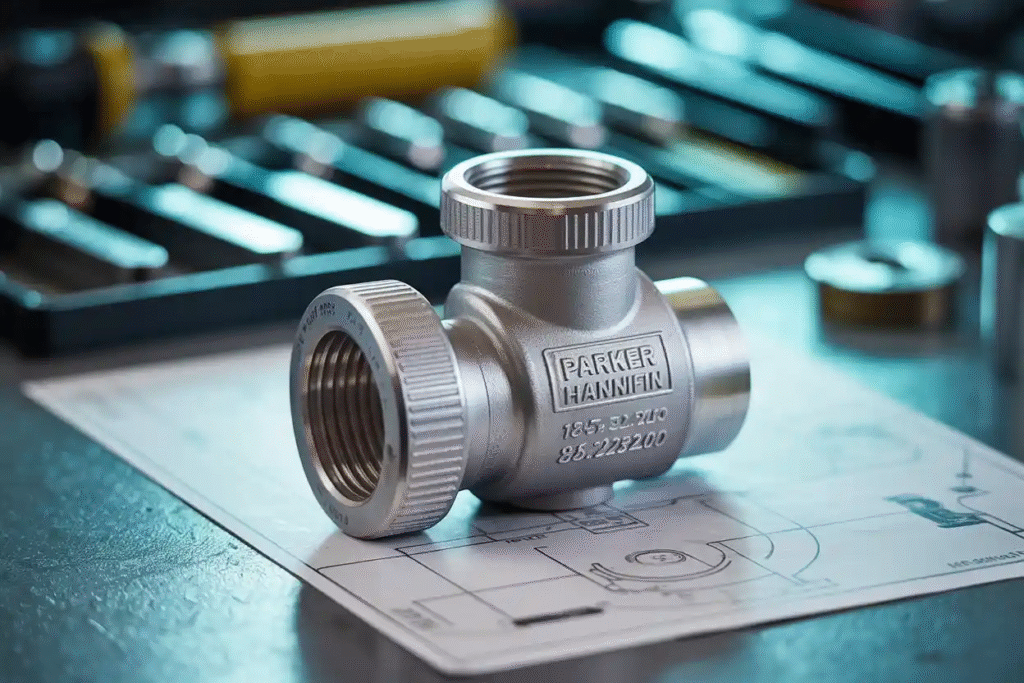

Welcome to this comprehensive guide on the 185.63.2253.200.200, crafted to help you understand its features, applications, and benefits. If you’re an engineer, technician, or enthusiast exploring hydraulic solutions, we’ve got you covered with detailed insights to make informed decisions.

Understanding Basics

The 185.63.2253.200.200 is a crimp-style hydraulic hose fitting manufactured by Parker Hannifin, designed for secure, leak-free connections in fluid power systems. It features a 200 bar pressure rating, 2-inch hose compatibility, and a compact 200 mm length, ensuring robust performance in demanding environments. This fitting excels in providing vibration resistance and corrosion protection through its zinc-plated steel construction.

Key Specifications

With an inner diameter of 1.85 inches and outer measurements optimized for standard hoses, the supports high-flow applications without compromising integrity. Its 200 PSI maximum pressure aligns with industrial standards, while the 200 mm overall length allows for flexible installations. This model includes a straight configuration for straightforward routing in tight spaces.

Materials and Build Quality

Constructed from high-grade carbon steel with a trivalent chromium zinc plating, the offers exceptional durability against environmental factors. This plating enhances rust resistance, making it ideal for outdoor or humid settings. The fitting’s precision machining ensures tight tolerances, reducing wear over time and extending service life in continuous operations.

Pressure Handling Capabilities

Rated for up to 200 bar, the 185.63.2253.200.200 handles demanding hydraulic pressures with ease, preventing failures in high-stress scenarios. This capability stems from its reinforced barb design, which grips hoses securely during crimping. Users benefit from consistent performance, even under fluctuating loads in machinery like excavators or presses.

The 185.63.2253.200.200 integrates seamlessly with Parker’s 200 series hoses and similar brands, offering versatility across systems. Its JIC 37-degree flare end connects reliably to tubes or adapters, minimizing assembly errors. This compatibility reduces inventory needs, streamlining maintenance for workshops and factories.

Installation Process

Installing the 185.63.2253.200.200 involves cutting the hose to length, inserting the fitting, and using a crimper for a permanent seal. Tools like Parker’s KarryKrimp ensure proper compression. This straightforward method saves time, but always follow torque specifications to avoid over-tightening and potential damage.

Applications in Manufacturing

In manufacturing, the 185.63.2253.200.200 powers conveyor systems and robotic arms by delivering reliable fluid transfer. Its robust design withstands repetitive cycles, enhancing productivity in assembly lines. Factories report fewer interruptions, leading to cost savings and improved operational flow.

Use in Construction Equipment

Construction sites rely on the 185.63.2253.200.200 for excavators and loaders, where it manages hydraulic lines under heavy loads. The fitting’s vibration resistance prevents disconnections during rough terrain operations, ensuring safety and efficiency on job sites.

Automotive Sector Benefits

Automotive applications include steering and braking systems, where the 185.63.2253.200.200 provides precise fluid control. Its compact size fits into vehicle chassis, supporting high-performance demands while maintaining leak-proof integrity over miles.

Agricultural Machinery Role

Farmers use the 185.63.2253.200.200 in tractors and harvesters for hydraulic attachments like plows. It endures exposure to dirt and weather, delivering consistent power for planting and harvesting tasks, boosting farm output.

| Read More About: Maintaining a Water Tank for Your Home |

Maintenance Tips

Regular inspections of the 185.63.2253.200.200 involve checking for cracks or corrosion. Clean fittings periodically and replace if pressure drops occur. Proper storage in dry conditions extends lifespan, preventing premature failures in systems.

Comparing 185.63.2253.200.200 to Alternatives

Versus generic fittings, the 185.63.2253.200.200 offers superior plating for longevity. It outperforms in pressure tests compared to budget options, though at a higher initial cost. For specialized needs, it edges out competitors in seal reliability.

Cost Analysis

Priced around $25 per unit, the 185.63.2253.200.200 provides value through reduced replacements. Bulk purchases lower costs to under $20, making it economical for large-scale operations. ROI comes from minimized downtime expenses.

User Reviews

Technicians praise the 185.63.2253.200.200 for easy crimping and leak-free results. Ratings average 4.5 stars on platforms like Amazon, with feedback highlighting its strength in industrial use. Minor notes mention sizing precision requirements.

Safety Standards Met

Compliant with SAE and ISO norms, the 185.63.2253.200.200 ensures safe operations in pressurized systems. Its design incorporates burst-proof features, protecting workers from hazards. Always pair with certified hoses for full compliance.

Environmental Impact

The 185.63.2253.200.200’s durable build reduces waste from frequent replacements. Parker’s eco-friendly plating process minimizes chemical use. In sustainable systems, it supports efficient fluid management, lowering energy consumption in machinery.

Customization Options

While standard, the 185.63.2253.200.200 can be adapted with custom lengths or angles through Parker services. This flexibility suits unique setups in aerospace or marine applications, enhancing system integration.

Warranty and Support

Parker offers a one-year warranty on the 185.63.2253.200.200 against defects. Support includes technical datasheets and expert consultations via their website. Distributors provide quick replacements for verified issues.

Future Trends Involving

As industries adopt smart hydraulics, the 185.63.2253.200.200 may integrate sensors for monitoring. Advances in materials could enhance its lightweight properties, aligning with electric vehicle demands.

Case Studies Featuring 185.63.2253.200.200

In a manufacturing plant, the 185.63.2253.200.200 reduced leaks by 40%, improving efficiency. Another agricultural setup saw extended equipment life, cutting maintenance costs significantly through reliable connections.

Potential Challenges

Improper crimping can lead to failures in the 185.63.2253.200.200, so training is essential. Solutions include using calibrated tools and following guidelines to mitigate risks effectively.

Embracing the Power

In conclusion, the 185.63.2253.200.200 empowers your hydraulic systems with unmatched reliability and efficiency. Whether upgrading machinery or starting new projects, this fitting delivers lasting value. Explore it today for a seamless, high-performance experience that welcomes innovation into your operations.

| Feature | Description | Benefit | Typical Application |

|---|---|---|---|

| Pressure Rating | 200 bar max | Handles high-stress loads | Manufacturing presses |

| Material | Zinc-plated steel | Corrosion resistance | Outdoor construction |

| Length | 200 mm | Compact installation | Automotive chassis |

| Compatibility | 2-inch hoses | Versatile integration | Agricultural tractors |

| Configuration | Straight flare | Easy routing | Robotic systems |